The Evolution of Industrial Tools: Shaping the Future of Manufacturing

- Home

- The Evolution of Industrial Tools: Shaping the Future of Manufacturing

The Evolution of Industrial Tools: Shaping the Future of Manufacturing

- Gordon Richards

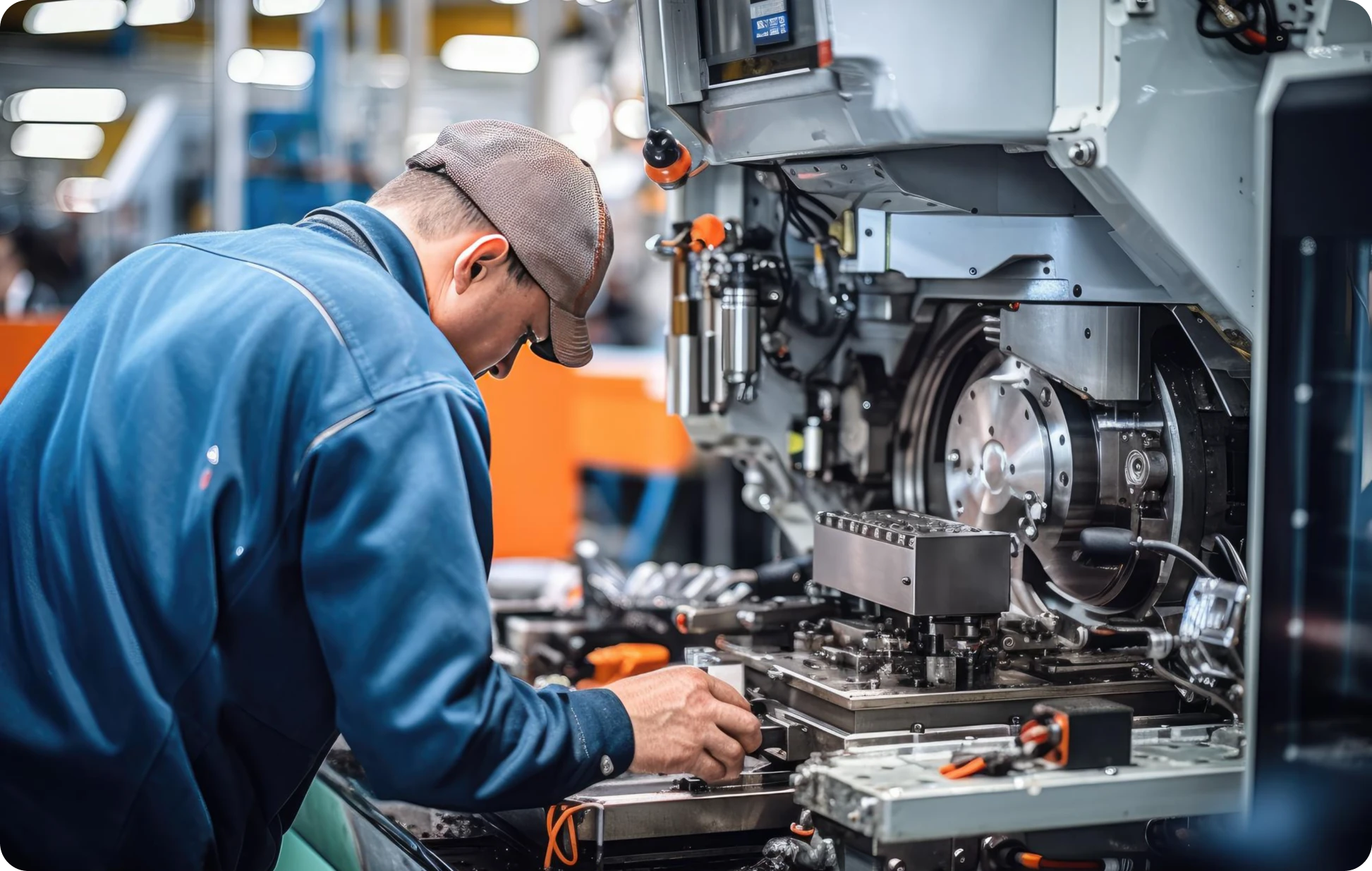

The landscape of manufacturing is in a constant state of flux, driven by relentless innovation and the demand for greater efficiency. At the heart of this transformation lies the evolution of industrial tools. For centuries, tools have been the fundamental extension of human capability, enabling the creation of everything from simple goods to complex machinery. Today, we are witnessing an unprecedented acceleration in their development, moving far beyond mere mechanical advantage to embrace digital intelligence and advanced material science.

This rapid evolution is not just about making existing processes faster; it's about fundamentally rethinking how products are designed, produced, and maintained. Manufacturers worldwide face pressures to enhance precision, reduce waste, and improve worker safety, all while navigating increasingly complex supply chains. The traditional workshop, once characterized by manual labor and standalone machinery, is giving way to interconnected systems where every component, including the tools themselves, plays a vital role in an integrated ecosystem.

The advent of smart tools and automation has particularly revolutionized the factory floor. These aren't just robust maintenance tools or shop tools anymore; they are sophisticated instruments equipped with sensors, data processing capabilities, and connectivity. This shift allows for real-time monitoring, predictive analytics, and adaptive manufacturing processes, transforming how operations are managed. It underscores the critical need for a reliable factory supply chain to support these advanced systems.

Ensuring operational continuity and embracing these technological leaps requires more than just acquiring new tools; it demands access to high-quality hardware supplies and equipment parts. Companies like Colorado Industrial Supply LLC understand that the foundation of modern manufacturing success rests on the availability of dependable components that integrate seamlessly with evolving tool technologies. Their commitment helps businesses maintain peak performance and adapt to the demands of a dynamic industrial environment.

The Digital Transformation of Workshop Floors

The integration of digital technologies has ushered in a new era for industrial tools, fundamentally reshaping workshop floors. We are seeing a widespread adoption of tools embedded with IoT (Internet of Things) sensors, enabling real-time data collection on performance, usage, and wear. This data feeds into analytics platforms, allowing for proactive maintenance tools scheduling, optimizing operational efficiency, and significantly reducing unexpected downtime. Such connectivity transforms individual tools into intelligent nodes within a larger, interconnected manufacturing network, fostering an environment of continuous improvement and responsiveness.

Furthermore, robotic automation and collaborative robots, or cobots, are becoming increasingly common. These advanced systems work alongside human operators, taking on repetitive, strenuous, or hazardous tasks with unparalleled precision and consistency. This not only boosts productivity but also significantly enhances workplace safety, freeing human workers to focus on more complex, value-added activities. The synergy between human expertise and robotic accuracy is defining the next generation of manufacturing capabilities, driven by ever more sophisticated industrial accessories that extend the functionality of these machines.

Advanced Materials and Ergonomics in Tool Design

Modern industrial tools are not only smarter but also physically superior, thanks to breakthroughs in material science. The use of lightweight yet incredibly durable materials, such as advanced composites, specialized alloys, and ceramics, significantly enhances tool performance and longevity. These materials allow for tools that are easier to handle, resistant to extreme conditions, and capable of withstanding rigorous industrial demands, thereby extending their service life and reducing the frequency of replacements. This focus on material innovation directly translates into improved operational reliability and reduced total cost of ownership for businesses.

Beyond material strength, ergonomic design has become a paramount consideration in tool development. Tools are now engineered with human factors in mind, focusing on user comfort, reduced fatigue, and prevention of repetitive strain injuries. Features like vibration dampening, optimized grip designs, and balanced weight distribution ensure that operators can work more effectively and safely over longer periods. This human-centric approach to tool design not only improves worker well-being but also contributes directly to increased productivity and higher quality output across various industrial applications.

Sustainability and Efficiency in Tool Operations

The drive for sustainability is profoundly influencing the design and operation of industrial tools. Manufacturers are increasingly prioritizing energy-efficient designs that consume less power, reducing the environmental footprint of production processes. This includes developing tools with advanced motor technologies and smart power management systems that optimize energy use based on real-time operational needs. The goal is to minimize waste not only in terms of energy but also in raw construction materials and consumables throughout the manufacturing lifecycle, promoting a more circular economy.

Moreover, the emphasis on sustainability extends to the entire lifecycle of industrial tools, from their manufacturing to disposal. This involves designing tools for easier repair and maintenance, promoting modularity to allow for component replacement rather than full tool disposal, and exploring responsible sourcing of materials. These practices contribute to a more environmentally conscious industrial sector, aligning operational efficiency with ecological responsibility. The commitment to such sustainable practices reflects a forward-thinking approach that benefits both businesses and the planet.

The continuous evolution of industrial tools is a cornerstone of modern manufacturing progress, driving unprecedented levels of efficiency, precision, and safety. From intelligent automation to advanced material science and ergonomic design, these innovations are fundamentally reshaping how industries operate and compete in a global marketplace.

Embracing these advancements is crucial for businesses aiming to optimize their production processes, reduce operational costs, and foster a safer working environment. The strategic integration of cutting-edge tools and technologies empowers companies to meet complex demands and maintain a competitive edge.

As manufacturing continues its transformative journey, the role of a reliable tool distributor remains indispensable. Companies like Colorado Industrial Supply LLC are vital partners, providing the essential equipment parts and innovative solutions necessary to navigate this evolving landscape and build the future of industry.

Colorado Industrial Supply

Colorado Industrial Supply

Comments 0